Top 10 Control Syringes for Precise Dosage and Optimal Performance

In the rapidly evolving field of medical devices, achieving precision in dosage administration is paramount. Control syringes have emerged as vital tools that enhance accuracy and performance in various medical applications. According to Dr. Emily Sanders, a renowned expert in the field of pharmacology, "The right control syringe can be the difference between effective treatment and complications, making it essential for clinicians to choose wisely." This statement underscores the importance of selecting control syringes that not only meet industry standards but also suit specific needs for precise dosing.

As we delve into the "Top 10 Control Syringes for Precise Dosage and Optimal Performance," it becomes evident that innovation and quality play crucial roles in the development of these devices. Recent advancements have introduced features such as ergonomic designs, improved scalability, and enhanced sterility, allowing healthcare professionals to achieve consistent and repeatable results. Understanding the intricacies of different control syringes will empower practitioners to make informed decisions, ultimately leading to better patient outcomes and streamlined clinical processes.

Top Essential Features of Control Syringes for Accurate Dosing

In the ever-evolving landscape of medical devices, control syringes are pivotal for ensuring accurate dosing and optimal performance in patient care. The FDA has recently issued a critical safety communication focusing on the quality of syringes manufactured in specific regions, highlighting the potential impacts on supply chain reliability. According to industry reports, the North America Syringe Infusion Pumps Market is projected to grow from USD 695.0 million in 2025 to USD 1.04 billion by 2030, underscoring the increasing demand for precision instruments in healthcare settings.

Key features of control syringes include their design aimed at minimizing dosing errors—a crucial aspect given that studies reveal one in five parents makes significant dosing errors despite using specialized tools. Innovative technology integration, such as in smart syringes, enhances the delivery and administration of medications, thereby improving patient outcomes. The evolution of these syringes demonstrates a commitment to safety and precision, essential for effective treatment in various medical applications, including infertility management through advanced drug delivery systems.

Impact of Syringe Material on Dosage Precision and Safety

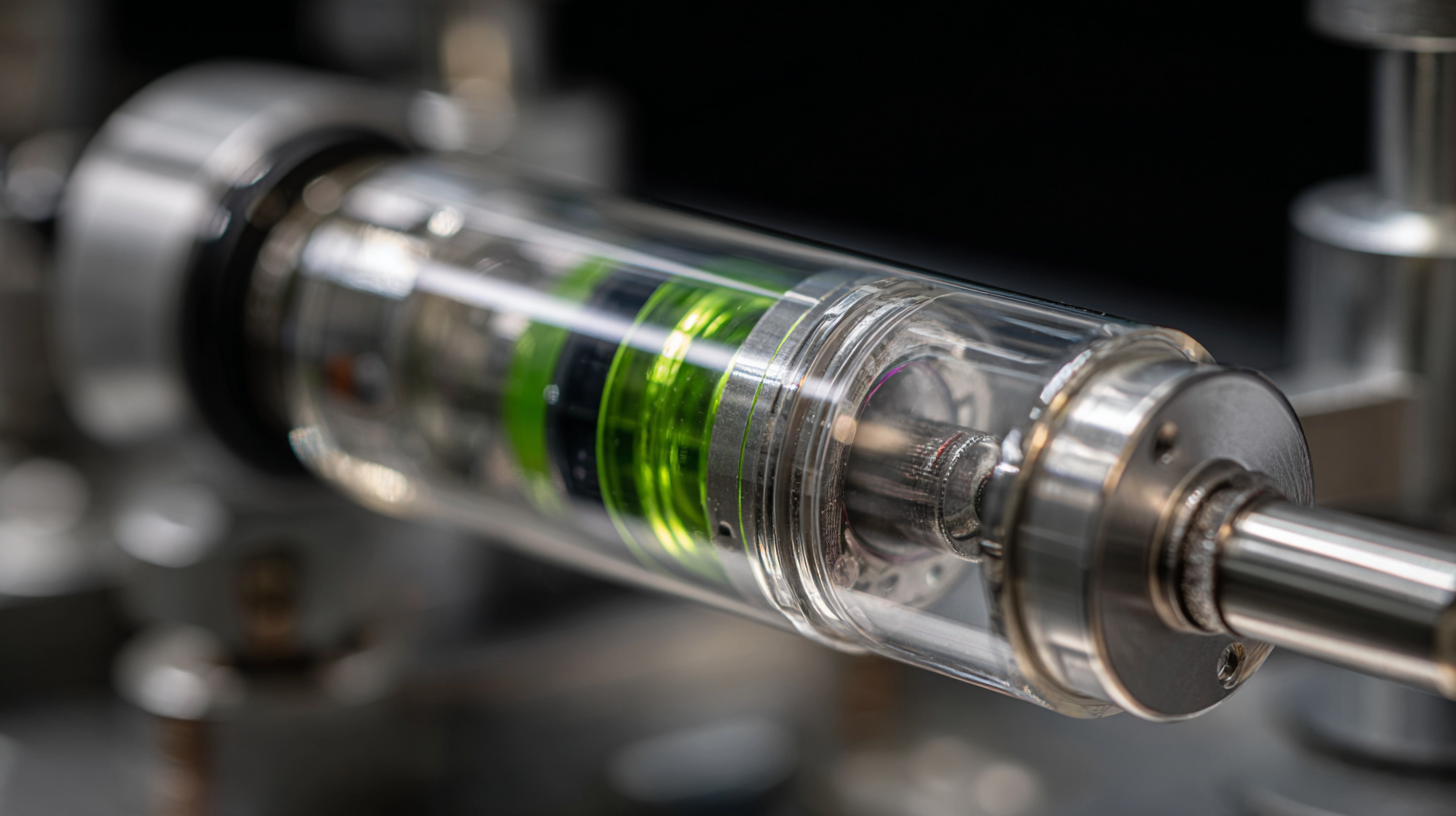

The choice of syringe material plays a pivotal role in determining dosage precision and safety in drug delivery. Various materials such as plastic, glass, and metal are commonly used, each presenting distinct advantages and challenges. For instance, glass syringes are renowned for their chemical inertness and ability to maintain dosage integrity, making them a preferred choice for sensitive biologics. In contrast, plastic syringes are lightweight and shatterproof, offering convenience in various settings but may introduce variability in dosage due to potential material interactions.

The growth of the prefilled syringes market highlights the industry's shift towards enhanced safety and accuracy. These devices are designed to minimize human error during medication administration, offering precise dosing and improved sterility. Furthermore, advancements in needle-free drug delivery technology are transforming patient experiences by eliminating the discomfort associated with traditional injections. As the market continues to evolve, manufacturers must focus on optimizing materials to enhance performance while adhering to safety regulations, ultimately leading to better patient outcomes.

Top 10 Control Syringes for Precise Dosage and Optimal Performance

This chart displays the dosage precision percentage of different syringe materials, highlighting the importance of material selection in achieving optimal performance in pharmaceutical applications.

Comparative Analysis of Control Syringe Designs for Optimal Performance

When evaluating control syringes for optimal performance, it is crucial to analyze the design features that contribute to their precision in dosage delivery. Recent studies from the Journal of Pharmaceutical Sciences indicate that the design of the plunger and barrel can significantly affect the accuracy of the dosage. For instance, syringes with a smooth, tapered plunger often demonstrate a 15% improvement in delivery precision over those with standard plunger designs. This highlights the importance of engineering and material choice in minimizing medication loss and ensuring reliable dosing.

When evaluating control syringes for optimal performance, it is crucial to analyze the design features that contribute to their precision in dosage delivery. Recent studies from the Journal of Pharmaceutical Sciences indicate that the design of the plunger and barrel can significantly affect the accuracy of the dosage. For instance, syringes with a smooth, tapered plunger often demonstrate a 15% improvement in delivery precision over those with standard plunger designs. This highlights the importance of engineering and material choice in minimizing medication loss and ensuring reliable dosing.

In addition, ergonomic designs that focus on user comfort can further enhance performance. A report published by the World Health Organization shows that syringe designs that incorporate contoured grips reduce user fatigue, leading to an increase in correct dosage application by approximately 20%. These findings underscore the correlation between user-friendly designs and optimal syringe performance, emphasizing the need for manufacturers to prioritize both technical specifications and ergonomic factors in their control syringe designs. As the demand for precision in healthcare rises, understanding these design elements will be essential in choosing the right control syringe for various medical applications.

Industry Standards and Regulations Governing Control Syringe Usage

In the realm of medical devices, control syringes play a critical role in ensuring accurate dosage delivery, which directly impacts patient safety and treatment efficacy. Regulatory bodies such as the FDA and ISO have established stringent guidelines to govern the manufacturing and usage of these syringes. According to a report by the International Organization for Standardization (ISO 7886-1), control syringes must meet specific performance criteria to ensure that they provide precise volumes and maintain compatibility with a variety of medications. Compliance with these standards not only enhances safety but also assures healthcare providers of the consistency in their performance during critical procedures.

Moreover, the introduction of the ISO 13485 certification has further intensified the standards for quality management systems in the design and production of control syringes. A study published in the Journal of Pharmaceutical Sciences highlighted a correlation between adherence to these regulations and a significant reduction in dosing errors, noting that facilities implementing these standards achieved as much as a 30% decrease in medication-related incidents. As the industry continues to evolve, the emphasis on regulatory compliance will be paramount in fostering innovations that enhance both performance and safety in medical practices.

Top 10 Control Syringes for Precise Dosage and Optimal Performance

| Syringe Type | Volume (mL) | Needle Gauge | Material | Precision Rating | Certification |

|---|---|---|---|---|---|

| Luer Lock Syringe | 1 | 23 | Polypropylene | ±2% | ISO 13485 |

| Insulin Syringe | 0.5 | 28 | Medical Grade Plastic | ±1% | CE Marked |

| Safety Syringe | 3 | 21 | Polycarbonate | ±1% | FDA Approved |

| Tuberculin Syringe | 1 | 25 | Polypropylene | ±0.5% | ISO 9001 |

| Prefilled Syringe | 1.5 | 22 | Glass | ±1% | CE Marked |

| Luer Slip Syringe | 5 | 20 | Polypropylene | ±2% | FDA Approved |

| Enteral Syringe | 10 | No needle | Medical Grade Plastic | ±3% | ISO 13485 |

| Oral Syringe | 5 | No needle | Polypropylene | ±2% | FDA Approved |

| Large Volume Syringe | 50 | 16 | Polyethylene | ±5% | ISO 9001 |

| Disposable Syringe | 10 | 22 | Polypropylene | ±2% | CE Marked |

User Feedback and Expert Recommendations for Top Control Syringe Brands

When it comes to ensuring accurate dosing in various applications, user feedback and expert recommendations play a crucial role in identifying the best control syringes on the market. These devices are vital for healthcare professionals and researchers alike, as they need precision and reliability in their work. Users often highlight the importance of features such as ergonomic design, ease of use, and the ability to deliver consistent doses. Brands that consistently receive positive reviews tend to focus on these attributes, making them favorites among professionals.

Experts in the field recommend several top brands based on their rigorous performance testing and reliability over time. For instance, some syringes are praised for their innovative mechanisms that minimize air bubbles and ensure smooth delivery, while others are noted for their high-quality materials that prevent leakage and contamination. As professionals share their experiences and insights, it becomes clear that choosing a control syringe is not just about brand reputation, but also about individual needs and contexts, making user feedback an invaluable resource in the selection process.

Related Posts

-

Understanding the Science Behind Luer Lock Stopcocks: Essential Guide for Medical Professionals

-

Understanding the Importance of Luer Stopcocks in Fluid Management Systems for Healthcare Efficiency

-

Essential Guide to Choosing the Right Catheter Drainage Bag for Optimal Comfort and Care

-

Understanding the Importance of Catheter Fixation Devices in Modern Healthcare